Introduction

In today's fast-paced world, the demand for high-performance electronic devices and equipment continues to rise. To meet this growing demand, engineers and manufacturers are constantly looking for ways to improve the efficiency and performance of power cables. One of the most innovative solutions to emerge in recent years is the multi-core power cable. This technology offers significant advantages over traditional single-core cables, providing higher power delivery, improved reliability, and enhanced flexibility. In this article, we will explore the benefits of multi-core power cables and how they are revolutionizing the way we power our devices.

Evolution of Power Cables

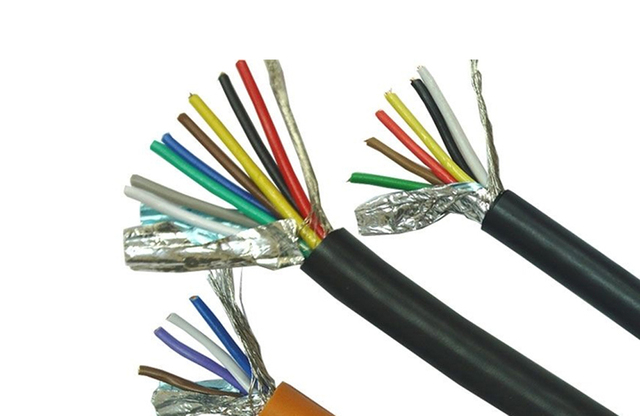

Power cables have been a critical component of electrical systems for decades, providing the essential connection between power sources and electronic devices. Traditionally, power cables consisted of a single core conductor surrounded by insulating materials to protect against electrical interference and environmental factors. While single-core cables have served their purpose well, they are limited in their ability to deliver high power levels efficiently.

As electronic devices become more powerful and energy-intensive, the demand for higher-capacity power cables has increased. This led to the development of multi-core power cables, which feature multiple core conductors within a single cable assembly. By incorporating multiple cores, these cables can deliver higher power levels while maintaining optimal efficiency and reliability.

Benefits of Multi-Core Power Cables

1. Higher Power Delivery: One of the key advantages of multi-core power cables is their ability to deliver higher power levels compared to single-core cables. By using multiple core conductors, these cables can distribute power more effectively, reducing the risk of voltage drops and ensuring consistent power delivery to connected devices. This is particularly important for applications that require high power output, such as industrial machinery, server systems, and electric vehicles.

2. Improved Reliability: Multi-core power cables offer enhanced reliability compared to single-core cables, thanks to redundant core conductors. In traditional single-core cables, a failure in the core conductor can result in a complete loss of power transmission. In contrast, multi-core cables can continue to function even if one of the core conductors fails, minimizing downtime and ensuring uninterrupted power supply. This increased reliability is crucial for mission-critical applications where system failures can have serious consequences.

3. Enhanced Flexibility: Multi-core power cables provide greater flexibility in terms of installation and configuration. With multiple core conductors housed within a single cable assembly, these cables can support a wide range of power distribution setups, including parallel connections, series connections, and customized configurations. This flexibility allows engineers and installers to tailor the cable layout to meet specific power requirements, making multi-core cables ideal for complex electrical systems with diverse power needs.

4. Reduced Electromagnetic Interference: Multi-core power cables are designed to minimize electromagnetic interference (EMI) and radio frequency interference (RFI) compared to single-core cables. The multiple core conductors within the cable assembly help to cancel out electromagnetic fields and reduce signal distortion, resulting in cleaner power transmission and improved signal integrity. This is particularly advantageous for sensitive electronic devices that are susceptible to EMI/RFI, such as medical equipment, telecommunications systems, and audio/video devices.

Applications of Multi-Core Power Cables

The versatility and performance benefits of multi-core power cables make them suitable for a wide range of applications across various industries. Some common applications include:

1. Industrial Automation: In industrial automation systems, multi-core power cables are used to connect control panels, motors, sensors, and other components. https://www.jiangyuancables.com/factory/ and reliability of multi-core cables make them ideal for powering heavy machinery and equipment in manufacturing plants, warehouses, and production facilities.

2. Data Centers: Data centers rely on robust power distribution systems to support the continuous operation of servers, networking equipment, and storage devices. Multi-core power cables are essential for delivering the high power levels required to keep data centers running efficiently and reliably.

3. Renewable Energy: The renewable energy sector, including solar and wind power generation, relies on multi-core power cables to connect solar panels, wind turbines, and energy storage systems to the grid. Multi-core cables help maximize power output and ensure seamless integration of renewable energy sources into the existing power infrastructure.

4. Electric Vehicles: Electric vehicles (EVs) require high-capacity power cables to support fast charging and efficient energy transfer between the vehicle's battery and charging station. Multi-core power cables are essential for enabling rapid charging speeds and extending the driving range of electric vehicles.

5. Aerospace and Defense: In aerospace and defense applications, multi-core power cables are used in aircraft, spacecraft, military vehicles, and communication systems. The enhanced reliability and EMI/RFI protection of multi-core cables make them well-suited for critical missions where system performance is paramount.

Future Trends and Innovations

As technology advances and power requirements continue to evolve, we can expect to see further innovations in multi-core power cable design and manufacturing. Some emerging trends and developments in this field include:

1. Higher Power Density: Manufacturers are working on developing multi-core power cables with increased power density to support the growing demand for higher power levels in compact electronic devices. By optimizing the design and materials used in the cable assembly, engineers can achieve greater power output without sacrificing efficiency or reliability.

2. Smart Power Cables: The integration of smart technologies, such as sensors, microcontrollers, and communication modules, into multi-core power cables is a promising trend in the industry. Smart power cables can provide real-time monitoring of power consumption, temperature, and performance metrics, enabling predictive maintenance and remote diagnostics for enhanced system reliability.

3. Eco-Friendly Materials: The shift towards sustainable and eco-friendly materials in power cable manufacturing is gaining momentum. Manufacturers are exploring new materials and production methods to reduce the environmental impact of multi-core power cables, making them more energy-efficient and recyclable.

4. Wireless Power Transfer: While traditional multi-core power cables rely on physical connections for power transmission, wireless power transfer technology is emerging as a viable alternative. By using electromagnetic induction or resonance coupling, wireless power transfer systems can deliver power wirelessly to electronic devices, eliminating the need for traditional cables altogether.

Conclusion

Multi-core power cables represent a significant advancement in power distribution technology, offering higher power delivery, improved reliability, and enhanced flexibility for a wide range of applications. By harnessing the benefits of multi-core cables, engineers and manufacturers can optimize the performance of electronic systems, reduce downtime, and improve overall efficiency. As the demand for high-performance power solutions continues to grow, multi-core power cables are poised to play a crucial role in shaping the future of power distribution and energy management.